|

Subinventory Transfer TransactionsSubinventory Transfer transactions are used in Oracle Inventory to move material from one subinventory to another. If either or both subinventories are locator controlled then the movement has to be from a subinventory/locator to the destination subinventory/locator. The example taken in this section will illuminate this point.

FREE Trial Downloads of The Ultimate Guide!

The Ultimate Guide to an R12 Inventory Org is here!

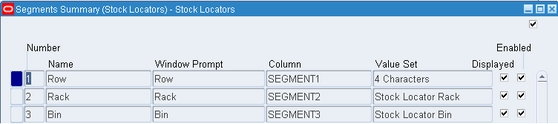

The Assessment Module is Free with any Combo Pack you buy! That's not all! There are more Bonus Offers... Transferring Defective Items to MRBIn an earlier section, Jennifer, the Inventory Lead at Office Smart Solutions (OSS) had defined a subinventory called Stores in the inventory organization called Office Smart Naperville (OSN). Based on the scenario that Jennifer learnt from the Inventory track lead Travis Kirchoff in the section on customizing transactions, she created another subinventory called MRB. Adding Stock Locators to MRB SubinventorySince MRB is meant to store defective material also referred to as "Rejects" in Quality Control parlance, OSS management has decided to segregate material into specific locators. Why? Because, some defective material need tighter control and closer monitoring than others. The Stock Locator is a Key Flexfield in Oracle Inventory. OSS has followed the usual convention to have three segments for this flexfield:

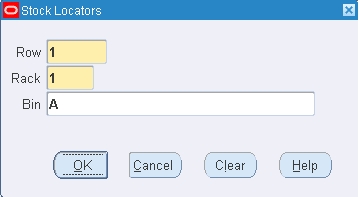

When defining the MRB subinventory, Jennifer sets the Locator Cobtrol field to Prespecified. She then creates the first locator in MRB subinventory as shown below.

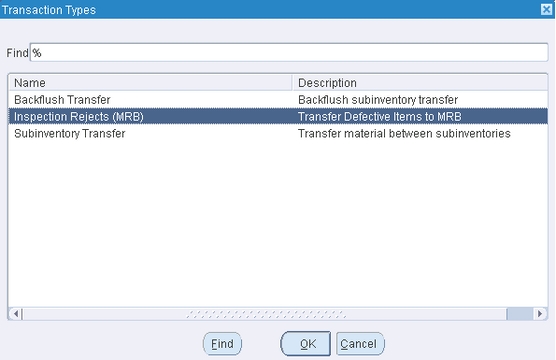

How does OSS want to name its stock locators? It depends on how their warehouse or storage areas are demarcated. It also depends on how they have defined the Value Sets for each of the three segments – Row, Rack and Bin. In this case Row, Rack and Bin can all have alphanumeric characters. This goes more into the domain of Flexfields, for which a separate section is required. Subinventory Transfer from Stores to MRBThe item LH101, which was introduced in the section on collection elements in Quality, is currently stored in the Stores Subinventory of inventory organization Office Smart Naperville (OSN). Upon inspection it was found that 2 units of LH101 are defective and need to be moved to the MRB subinventory, pending further action. When performing the subinventory transfer, Jennifer needs to specify the transaction Type. Typically the Type would have been Subinventory Transfer. Using the New Transaction TypeIn the section A New Transaction Type for Travis, Jennifer had created a new Transaction Type called Inspection Rejects (MRB). Since, the current transaction belongs to the business case for which the new transaction type was created, Jennifer selects this transaction type from the list of predefine transaction types.

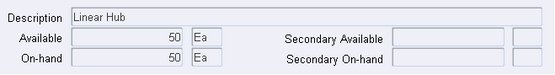

Jennifer then assigns the Source as MRB Material, the Transaction Source Type she had defined when creating the new transaction type. When conducting the transaction, she needs to assign the (from) Subinventory as Stores. The moment she does that, the screen displays the available on-hand balance.

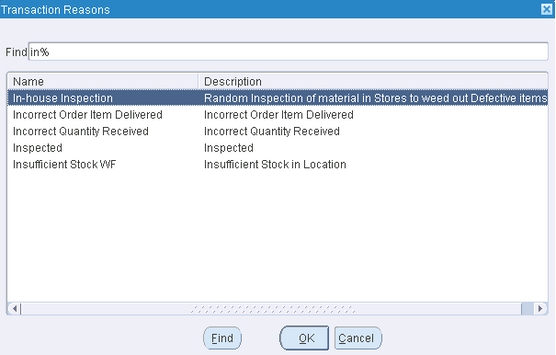

Need to Specify Stock LocatorHowever, the moment Jennifer enters the destination subinventory as MRB, the To Locator field becomes mandatory. This is because when defining the MRB subinventory the Locator Cobtrol field was set to Prespecified. Jennifer enters the stock locator code she had created earlier. Finally, Jennifer enters a reason in the Reason field from a predefined list of values. Here she finds the reason she had created after creating the new transaction type.

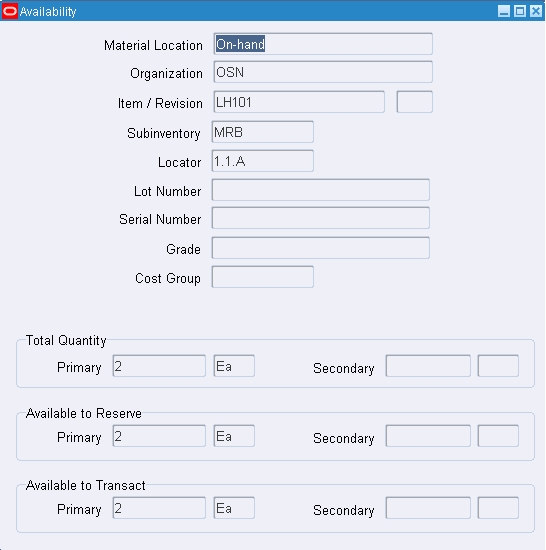

She selects the In-house Inspection reason name. Upon saving her work the transaction gets committed. Checking the On-hand BalanceWhen Jennifer verifies the on-hand balance she finds the MRB subinventory now has 2 units of LH101 in the specified locator.

Similarly, the Stores subinventory gets decremented by 2 units of LH101.

So, someone in the Quality department initiated this transaction. Where’s the documentary evidence seeking a material transfer? The answer to this lies in Move Orders. Next: The Move Order Previous: A New Transaction Type for Travis |