The Move Order

The Move Order was introduced in Oracle Applications 11i and has continued to exist ever since. Move orders are formal requests to move material within the same inventory organization.

We covered Transaction Source Types in an earlier section. Oracle Inventory provides two predefined source types to Move Orders

These source types are used with a specific type of Move Orders calledRequisition Move Orders. This brings us to the types of Move Orders.

FREE Trial Download!

The Start to End Video Guide to Implementing Oracle Inventory in R12

This version will help you explore and review the COMPLETE Video Tutorial... ALL 87 videos, for 1 Trial and 1 Day.

Once you like the Tutorial, select from any of the Subscription options here, to get your copy of the eLearning Video.

FREE Download

Detailed Course Topics for the Start to End VIDEO Tutorial

As on 12 February 2015...

4,800 Subscriptions

We are TRULY excited to share with you the Feedback we are getting on this Tutorial!

Types of Move Orders

There are three types:

Requisition Move Orders are used to manually create requests to move material. These move orders may have multiple lines each for a separate item. If the move order requires approval, then it cannot be transacted unless the planner for the specific item approves it. To approve move orders we need some additional setups. Therefore, we will take a look at it separately at the end of this page.

There is another step prior to transacting the Requisition Move Order. The material needs to be allocated. This means making an informed decision on which subinventory to source the material from and reserving it there. If picking rules have been set up in Oracle Inventory the allocation process will use these rules to determine the source subinventory.

Finally, the Requisition Move Order is ready for transacting. At this stage the user may choose to print a pick slip for the material handler to know where to get the material from.

Replenishment Move Orders pre-approved move orders that are created automatically by Oracle Inventory. These move orders get created when there is a requirement for material and any of the following inventory replenishment methods are used:

Now, since a move order is a tool for sourcing material within an inventory organization, Replenishment Move Orders are generated only when the material is sourced from another subinventory within the same inventory organization. For this the move order Source Type must be set as Subinventory.

Pick Wave Move Orders are used in Order Management. The Oracle Shipping Execution pick release process generates a Pick Wave Move Order to move the material from its source location to the Staging subinventory. In effect, this is a subinvenotry transfer through a pre-approved and ready to transact move order.

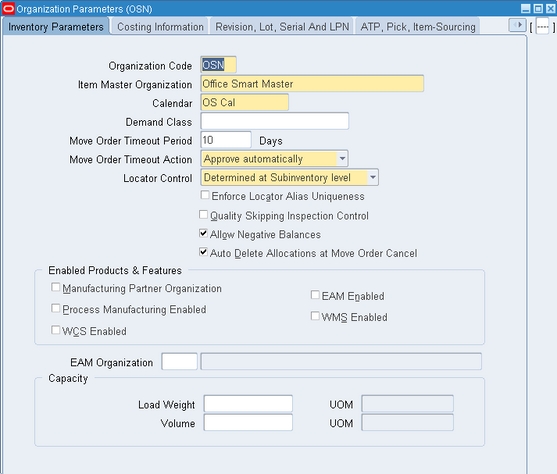

Move Order Setup at the Organization Parameter level

There move order approval process is governed by two parameters

The Move Order Timeout Period field specifies the number of days the Move Order waits for approval. In the screenshot above we see that for Office Smart Naperville, the Timeout Period has been set to 10 days. The first time the move order is created a notification is sent to the approver. If the approver does not take any action, then there will be a wait time of 10 days after which he will receive a second notification. Then after a second Timeout Period the move order is automatically accepted or rejected depending on the value in the Move Order Timeout Action field.

Office Smart’s Dilemma

The Naperville plant of Office Smart Solutions (OSS) called Office Smart Naperville or OSN, is in a dilemma. Travis Kirchoff, the Inventory Management track lead at is not so sure if the concept of Move Orders with approval would work for OSN. The work culture at OSN is not too familiar with having to seek approvals for every material transfer transaction. Travis therefore asks Jennifer to provide a demonstration of the concept on the Vision database.

The next section deals with Jennifer’s demo.

Next: The Requisition Move Order